In addition to the ready-made aluminium blocks we purchase, we also produce blocks for use in our production. We use DIN230 chemical composition.

Chemical composition analysis:

A SpectroMaxx analyser guarantees continuous control of the high-quality base material. The material composition analyser determines the composition of a given raw material to an accuracy of one tenth of one percent. This allows continuous quality to be maintained and coordinated.

Custom manufacturing and design:

Our own team of engineers designs the mould for each piece, which is manufactured in our own machining centre. Within up to 2 weeks of receiving the first designs, the customer will receive the first finished pieces.

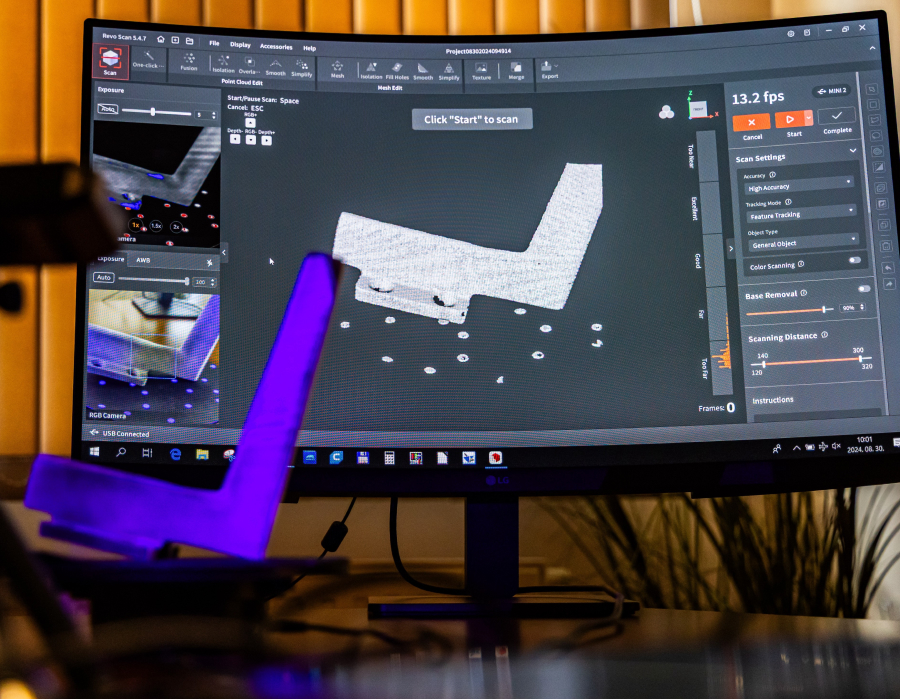

3D Scanning:

Using state-of-the-art 3D scanning technology, we digitise finished parts with sub-micron accuracy. The scanned data can be converted into STEP files, technical drawings, or complete models. This enables fast redesign, accurate reproduction of components, and efficient reverse engineering.

Coquille casting:

Ordered components are poured into coquilles. Products ordered by our customers are made with utmost care and more than 30 years of experience. The aluminium block is first heated to 680-750 degrees Celsius in crucibles with a capacity of 350 kg. The temperature is controlled by a fully automatic system, so the material is always available at the desired temperature. Moulds consist of both manual and hydraulically operated tools.

Grinding and Deburring:

We carefully remove all burrs created during the casting process and grind the entire surface to a perfectly smooth finish. With precise manual and machine processing, the parts are ideally prepared for further surface treatments – whether brushed, polished or powder-coated.

Industrial finishing machine for fine grinding:

This industrial machine plays a key role in fine surface finishing. Plastic grinding media refine castings to a perfectly smooth surface. With a diameter of more than 2 metres, the fully automated, industrial-scale system ensures high efficiency and consistent quality.

Stainless steel look and polishing:

Our partners can choose from a range of surface finishes. In our grinding and polishing department, we use dedicated tools and discs to achieve the desired texture.

For the stainless steel look, the grain direction is perfectly aligned with the shape of the casting. For polishing, we offer matte, high-gloss and chrome-like finishes.

Ball polishing:

This machine enables fully automated polishing. Steel balls of various sizes brighten the surface of the castings evenly, reaching areas that large polishing wheels cannot access.

The system automatically dispenses and circulates polishing compound and water, ensuring consistent high-quality results and a long-lasting shine.

Powder coating:

Our partners can also opt for powder-coated finishes. The complete RAL colour range is available, and the system is capable of applying acrylic coatings as well. Thanks to the fully automated pre-treatment process, the surface is perfectly prepared, ensuring an even, durable and visually appealing layer of electrostatic powder coating.

Surface finishes can be offered in a wide variety: matte, smooth, textured or high-gloss. This way, every product achieves a customised, premium-quality appearance.

Machining centre:

In addition to the design and manufacturing of moulds, this is where components are machined for which tolerances are very strict and an accuracy of a tenth of a millimetre is required. Also, this is where special inclination angles, bores, countersinks, and threads are formed on the products. Our machining centre is staffed exclusively by automatic machines, allowing us to produce the most complex parts.

Grit blasting:

Here has been a growing demand for grit-blasted surfaces in recent years. These types of surfaces can facilitate further machining, such as powder coating. Parts spend on average 2-4 minutes in the machine, depending on the roughness of the surface. Not only is it an excellent base for powder coating, but it also has a significant aesthetic role.

Final cleaning, quality controlling:

Cleaning is the last but highly important stage of the production process. It involves professionally removing the auxiliary materials used in manufacturing from the completed pieces. In addition to cleaning, this department also carries out quality control, which plays an essential role in maximising customer satisfaction. After thoroughly soaking the components, we clean them. In addition to the surface, each hole and thread is given special attention to ensure that the products can be secured without hindrance by the end user.